Why are high-temperature lithium-ion batteries more suitable for Autoclaves data...

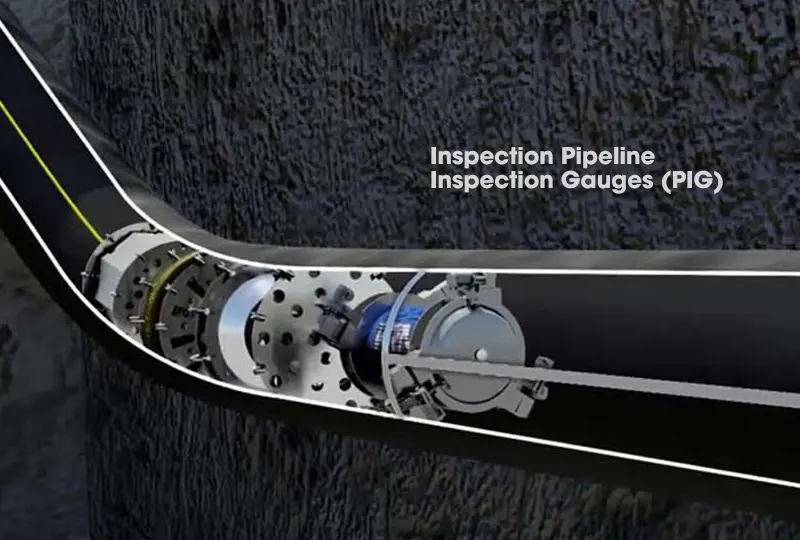

Read MoreHow does Inspection Pipeline Inspection Gauges (PIG) perform hydraulic propulsion?

The following are the general steps for hydraulic propulsion:

1. Install the PIG inlet on the pipeline. The entry port is usually a snap ring, magnetic rotating rod, or other device. This will ensure that the PIG can move smoothly in the pipeline and ensure the accuracy of the detection results.

2. Open the valve at the inlet of the pipeline and pump the liquid into the pipeline. A hydraulic station usually consists of a booster pump, a delivery pipeline that can be pushed through the pipeline, valves, and controllers.

3. The high pressure of the liquid pushes the PIG inside the pipeline and causes it to move forward along the pipeline track. During the detection period, PIG will collect data and parameters inside the pipeline and transmit them back to the computer for analysis.

4. After the inspection is completed, close the valve on the pipeline and discharge the liquid from the pipeline. At this point, the PIG can be removed from the inside of the pipeline and cleaned and maintained.

Extend Knownledges

What issues have lithium-ion batteries helped Autoclaves data loggers solve?

What issues have lithium-ion batteries helped Autoclaves data loggers solve?...

Read MoreAutoclaves data loggers how much voltage Li-ion battery?

Autoclaves data loggers how much voltage Li-ion battery? https://youtu.be/GSAtWWPmBRc The...

Read MoreWhat is the effect of lithium-ion batteries on Autoclaves data loggers?

What is the effect of lithium-ion batteries on Autoclaves data...

Read More