About ER Battery?

What is the difference in manufacturing process between ER common battery and ER high temperature battery?

For ordinary batteries, aluminum-plastic film is used as the casing packaging material.

For high-temperature batteries, the outer casing is made of high-temperature-resistant black leather.

Expand knowledge

About ER battery type use classification?

High temperature batteries can be divided into three categories according to their usage: capacity type, power type and high temperature type.

About aluminum plastic film material?

The pouch battery is packaged with aluminum-plastic film, which is a composite material and consists of three layers: nylon layer, aluminum foil layer, and heat-sealing layer.

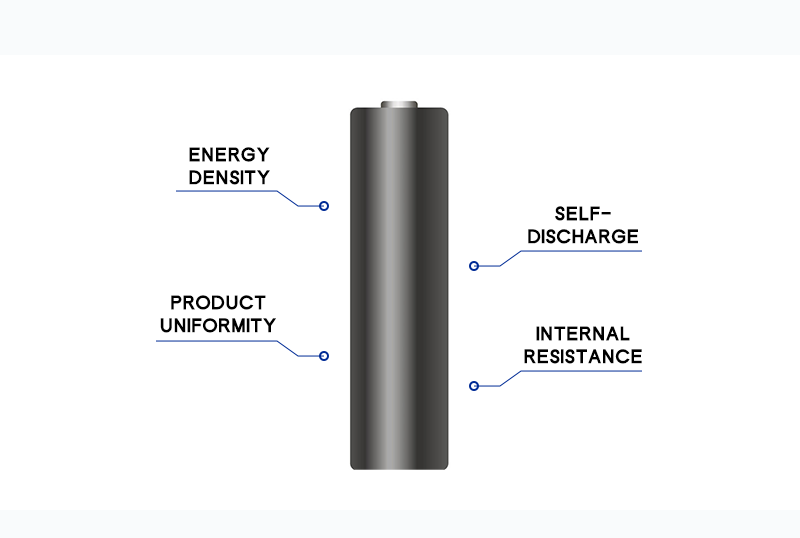

How to control energy density, product uniformity, self-discharge, and internal resistance in battery manufacturing?

Energy density: Lithium-sulfur battery has the highest energy density among primary batteries at present, with specific energy up to 590W·h/kg and 1100 (Wh/dm3).

Product uniformity: mass-produced batteries are controlled within a certain error range, and the error value is small. Maintaining the uniformity of battery performance during production can improve the yield rate of production, thereby controlling the occurrence of defective rates and reducing production costs.

Self discharge: the self discharge of ER battery is low, the annual self discharge rate is less than 1% under normal temperature, and the storage period can reach 15 years under the environment below 35 ℃.

Internal resistance: The internal resistance of the battery refers to the resistance to the current flowing through the battery when the battery is working.

Expand knowledge

About battery self-discharge?

There is no connection between the electrodes, and the extremely small amount of chemical substances in the battery will also react.

How safe are ER batteries?

ER batteries are recyclable and environmentally friendly batteries that are not easy to burn.

Expand knowledge

About battery safety?

The safety of the battery is mainly controlled in several aspects: during the cell manufacturing process, during the battery pack integration process, during the storage process, during the transportation process…

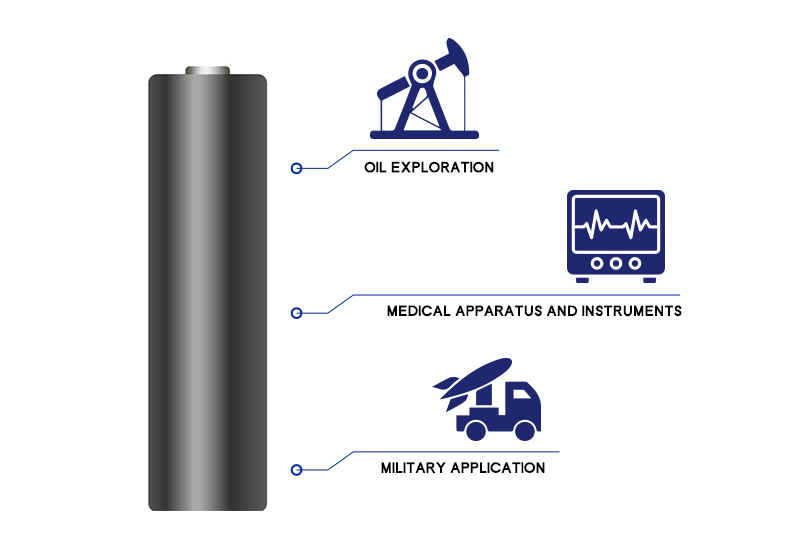

Where are ER battery applications used?

Lithium thionyl chloride batteries can be used in various fields, mainly in smart card meters (water, electricity, gas meters), computer supported power supplies, medical devices, wireless communications, oil drilling, portable communication equipment, scientific research instruments, remote control data collection systems, military applications and other electric equipment.

It is applied to oil and gas exploration in high temperature fields such as MWD (measurement while drilling), oil exploration, and whole well high-temperature environment.

Expand knowledge

About the application field of ER battery?

Lithium-sulfur batteries are mainly used in petrochemical industries such as oil exploration, geology and deep-sea exploration…

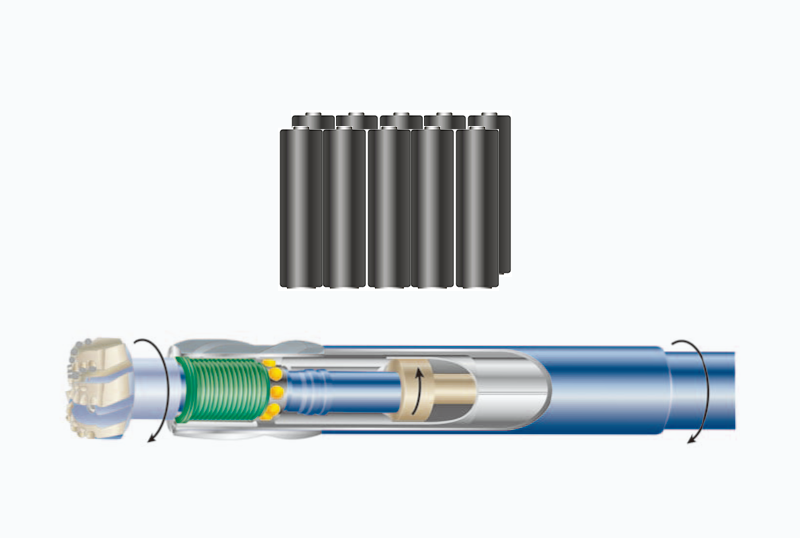

ER battery is used in which component part of MWD?

MWD tool power supply assembly.

MWD and logging while drilling (LWD) tools are powered by an autonomous power source, usually a battery. Drilling and logging services require batteries that can safely operate at high temperatures, raising the temperature limits at which they can power tools.

Expand knowledge

About MWD?

MWD means “Measure While Drilling”, which originally meant measuring the main parameters of borehole trajectory while drilling,

ER Battery Production Brief Workflow

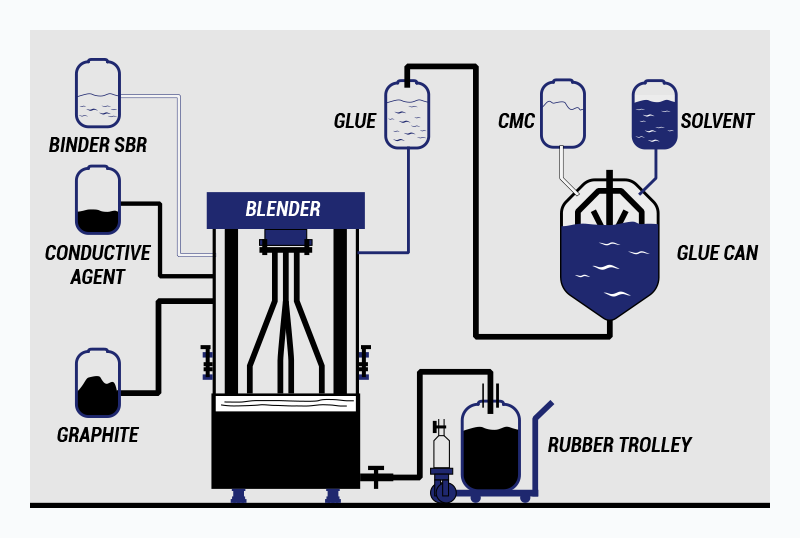

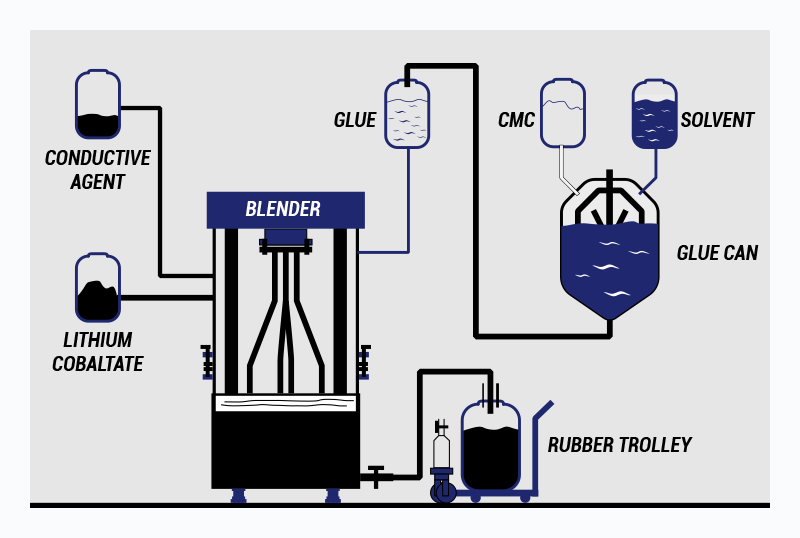

Step1: Cathode homogenate

The main components of the negative electrode dressing are carbon and adhesive.

Prepare the materials, mix the negative solid battery materials evenly, then add the solvent, and stir them into a paste through a vacuum mixer.

After fully mixing and dispersing, compound slurry is formed.

Expand knowledge

About carbon?

There are many kinds of carbon anode materials, mainly including natural graphite, artificial graphite, hard carbon, soft carbon, carbon nanotubes, graphene, etc.

About adhesive?

The binder is an auxiliary material for dispersing and binding in the battery.

Step2: Positive homogenate

The main components of the positive electrode dressing are lithium, adhesive and conductive agent.

Prepare the materials, mix the positive solid battery materials evenly, then add the solvent, and stir them into a paste through a vacuum mixer.

After fully mixing and dispersing, compound slurry is formed.

Expand knowledge

About lithium?

Lithium (Lithium) is a metal element located in Group IA of the second period of the periodic table.

About conductive agent?

The conductive agent is to ensure that the electrode has good charge and discharge performance.

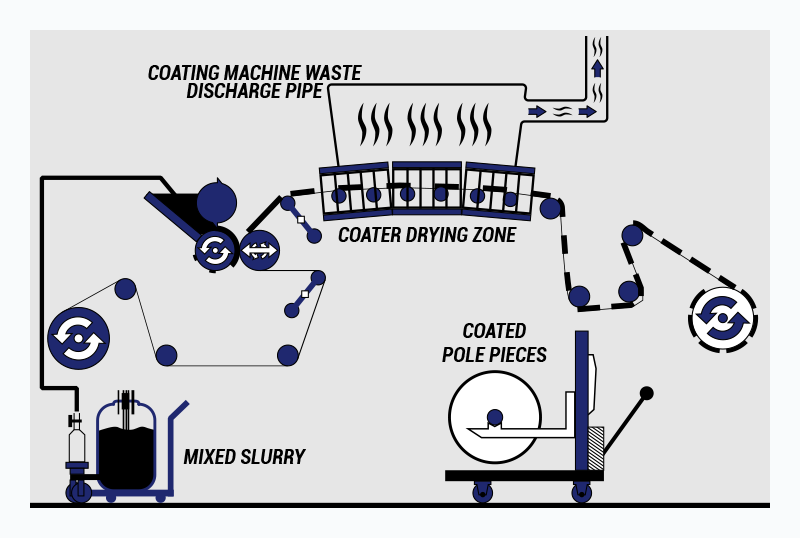

Step3: Coating

The prepared slurry is uniformly coated on the collecting fluid with the specified thickness.

Aluminum foil for positive pole and copper foil for negative pole.

Below is the baking sheet to evaporate the water and other volatile organic compounds in the slurry.

Expand knowledge

About aluminum foil?

The key material in the positive electrode of lithium battery-aluminum foil.

About copper foil?

Copper foil is a key material for the negative electrode of lithium-ion batteries, which has an important impact on the energy density and other properties of the battery.

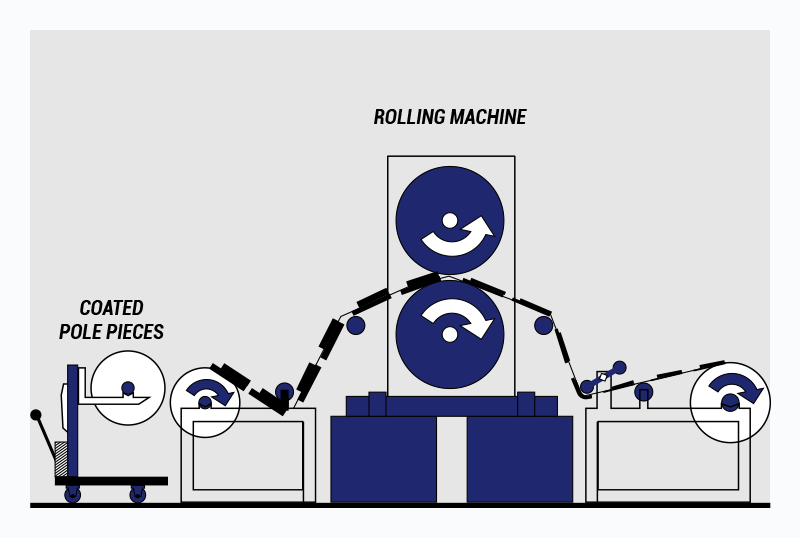

Step4: Rolling

The slurry after coating is relatively loose, and to increase the energy density of lithium batteries, it is necessary to control the thickness of the pole piece.

The coated pole piece is pressed and equalized by hydraulic pressure and counter-rolling method, so as to increase the energy density of the battery.

The flatness of the pole piece will directly affect the effect of the subsequent slitting process, and the uniformity of the active material of the pole piece will indirectly affect the performance of the battery cell.

Expand knowledge

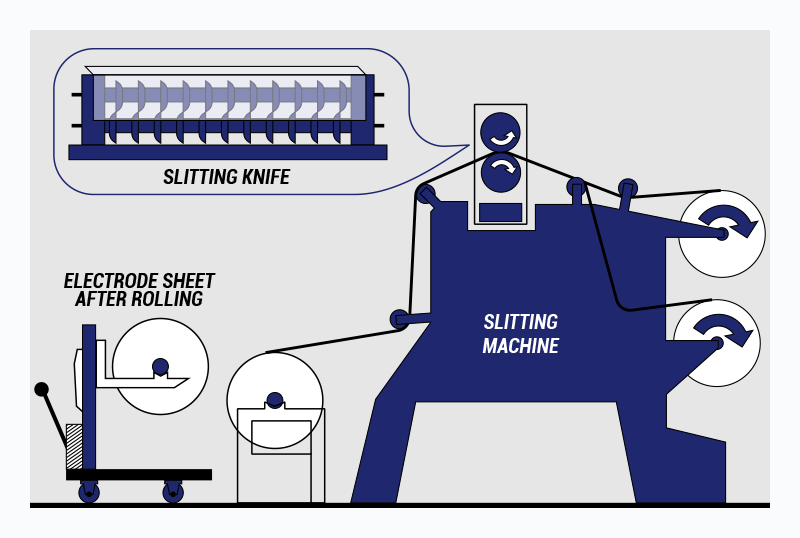

Step5: Slitting

The whole roll of pole piece is cut into several narrow pieces of required width continuously.

After slitting, the edges are required to be flat.

Expand knowledge

What are the requirements for the edge after slitting?

The pole piece encounters shear failure during slitting, and the flatness of the edge after slitting (no burr, no buckling) is the key to inspecting the performance of the slitting machine.

About the slitting machine?

The pole piece slitting machine is the equipment for slitting the rolled battery pole piece according to the battery specification.

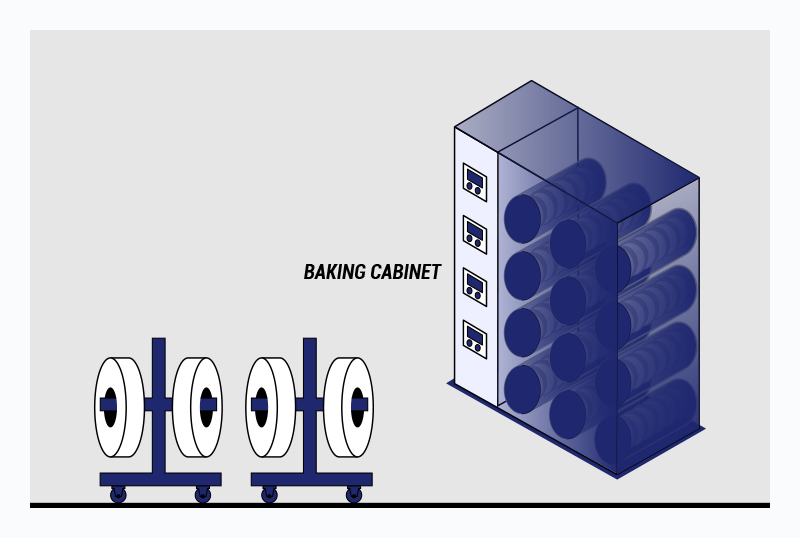

Step6: Negative electrode/positive electrode baking

After the pole piece is in contact with the air, it will absorb the moisture in the air, causing the pole piece to become thicker, and the moisture will be removed by baking.

Put the pole pieces into the oven to dry.

Expand knowledge

About battery vacuum baking?

Lithium battery electrolyte is an organic substance without water molecules.

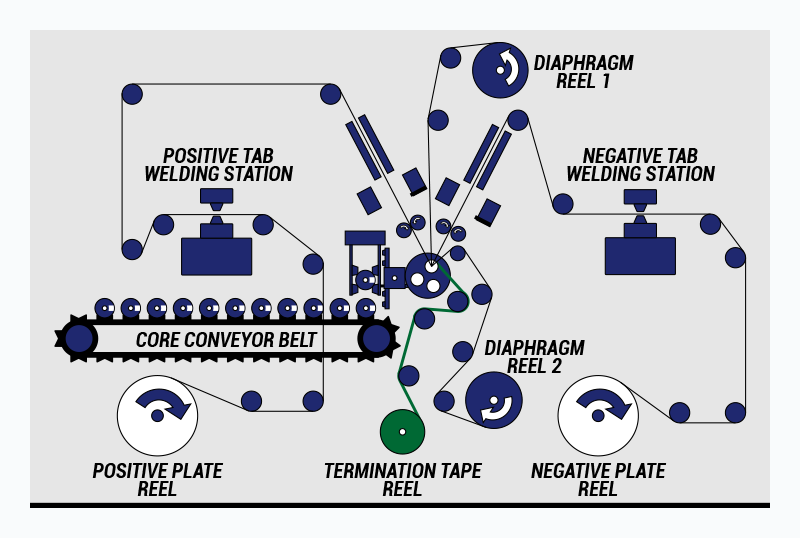

Step7: Winding

Place them in order from top to bottom. Positive electrode sheet/diaphragm/negative electrode sheet/diaphragm.

Wrapped by winding. Form battery cells.

Expand knowledge

About lithium battery winding machine?

The important technology of lithium-ion battery winding equipment is to control the tension of the separator and plate and to wind at a constant speed.

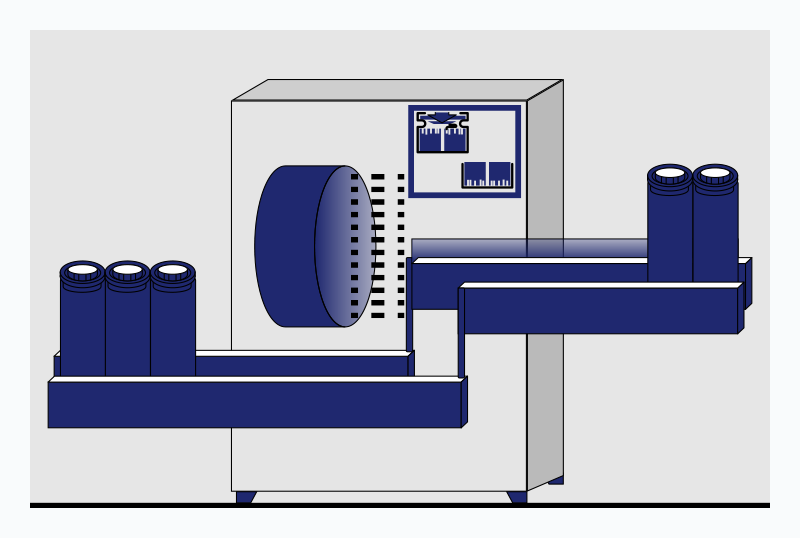

Step8: Check alignment

Carry out machine vision alignment inspection of lithium battery pole pieces to avoid waste of finished product defects.

Expand knowledge

About the machine vision alignment detection of lithium battery pole pieces?

In the winding process of lithium battery production, the positive and negative electrodes are placed in the separator.

About machine vision alignment inspection requirements?

There are four main points for winding degree monitoring…

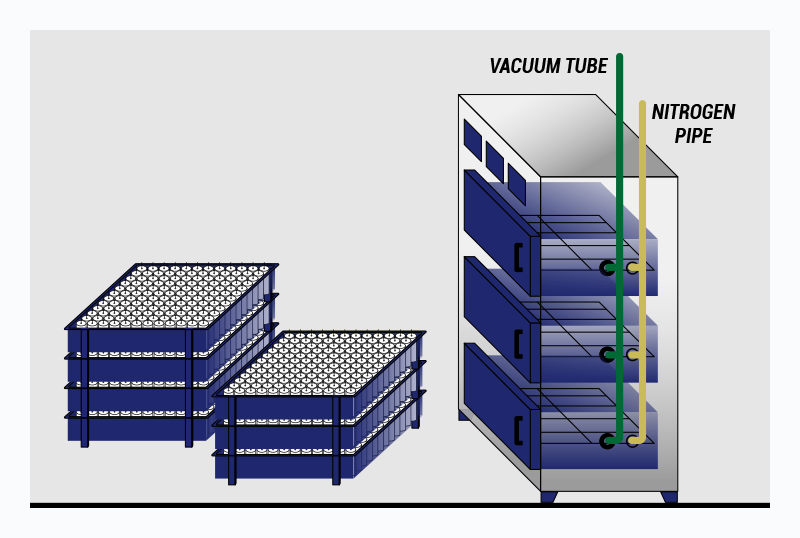

Step9: Insert the battery housing

Put the completed batteries into the steel case.

Expand knowledge

About lithium battery steel case?

As a key component of the battery system, the battery case plays a role in fixing and fully sealing the internal electrochemical system.

About the battery case material?

The main function of the battery pack case is to carry the battery pack. Protect from damage from external bumps, shocks and extrusions.

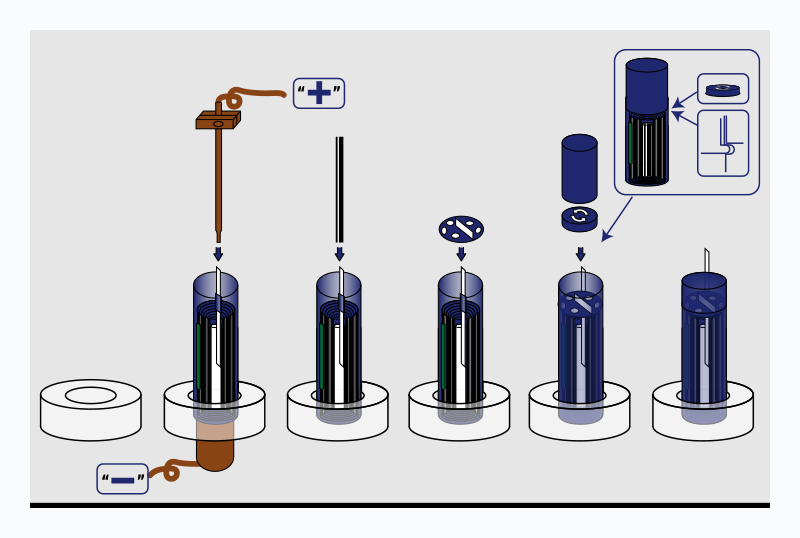

Step10: Spot welding

Weld the positive and negative tabs to the aluminum cover.

Use laser welding to weld the cover plate and the aluminum shell.

A liquid injection hole is reserved on the cover for liquid injection.

Expand knowledge

About laser welding?

The reasonable selection of welding methods and processes in the battery production process is very important, which will directly affect the production cost, quality and safety performance of the battery.

About the reserved liquid injection hole?

The process of injecting the electrolyte (lithium hexafluorophosphate, etc.) into the battery according to the required amount by reserving the injection hole is divided into primary injection and secondary injection.

Step11: Electric core baking

Put the electric core into the baking machine.

Bake to remove moisture.

Expand knowledge

About the role of battery baking?

In the multiple production processes of lithium batteries, the positive and negative electrodes, batteries and batteries are vacuum baked several times to remove the moisture as much as possible.

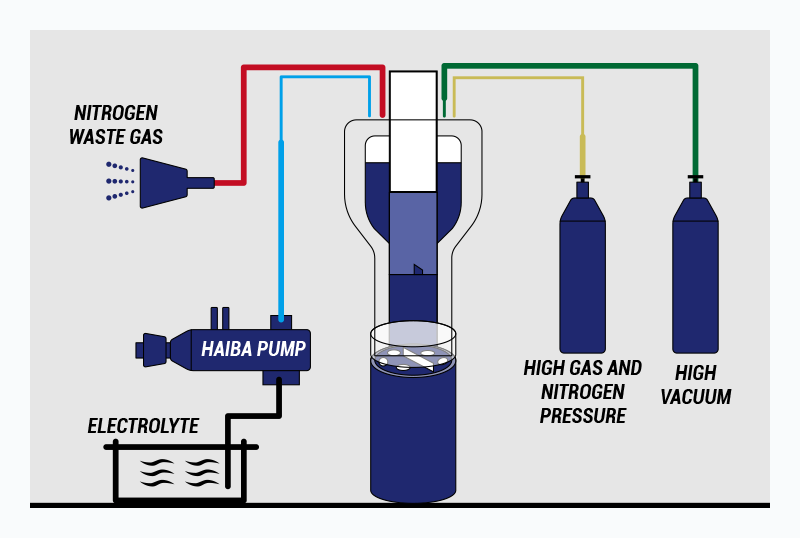

Step12: Inject electrolyte

For hard shell batteries, inject a little electrolyte first. Perform the first short charge.

Charging is completed, and the second liquid injection is performed.

After the second liquid injection is completed, seal the liquid injection hole with steel balls.

Expand knowledge

About hard case batteries?

Hard-pack lithium-ion batteries are subdivided into cylindrical and square.

About the pouch battery?

Soft-pack lithium-ion battery packs have better safety performance.

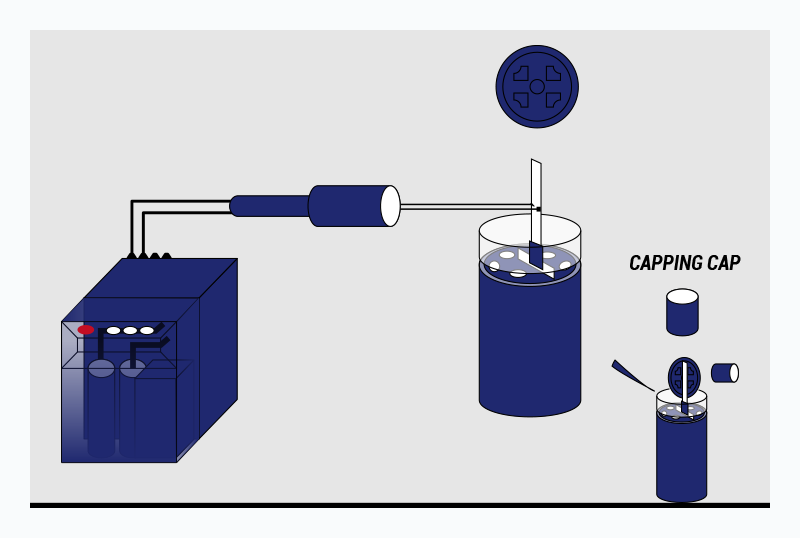

Step13: Weld, cap

Welding tension: ≥6N

Welding appearance requirements: no false welding, welding scorching, welding penetration, fracture.

Expand knowledge

About the welded cap?

The lithium battery cap is a component of the lithium battery, which acts as a positive conductive terminal on the lithium battery, acts as a safety valve, and also provides a battery sealing function.

Regarding welding appearance requirements?

Welding Appearance: No void, welding scorching, welding penetration, welding slag, no electrode dome, fracture

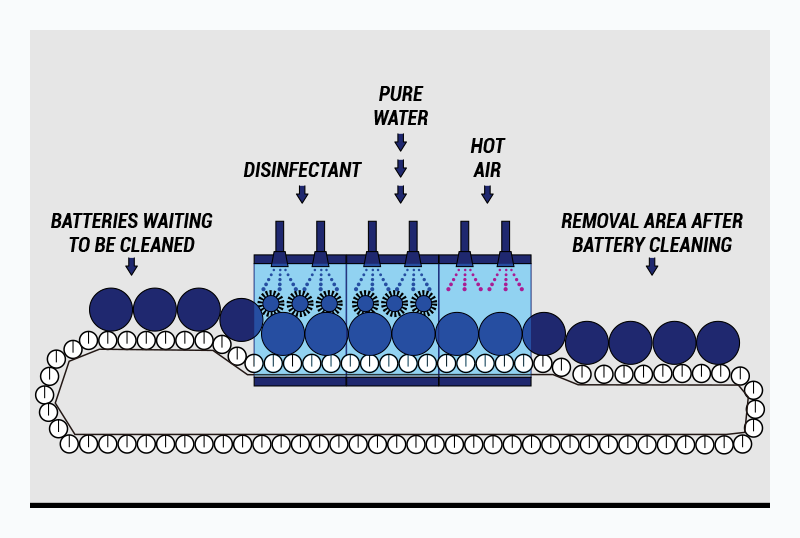

Step14: Plasma cleaning

Cleaning steps:

1. The battery is placed in the area to be cleaned.

2. After cleaning solution.

3. After purified water.

4. After hot air.

5. Flow into the battery removal area.

Expand knowledge

About plasma cleaning?

Plasma cleaning is a dry cleaning that relies on the “activation” of active ions in the plasma to remove stains.

About the role of plasma cleaning?

The ion cleaning method can effectively remove dirt, dust and other substances on the end face of the battery pole, and prepare for battery welding to reduce bad welding.

Step15: Dry/dry storage

The battery is placed in a drying room to remove moisture.

Let stand for some time in the drying room.

Expand knowledge

About the drying principle?

Enter the drying room to remove moisture, and let it stand for some time in the drying room.

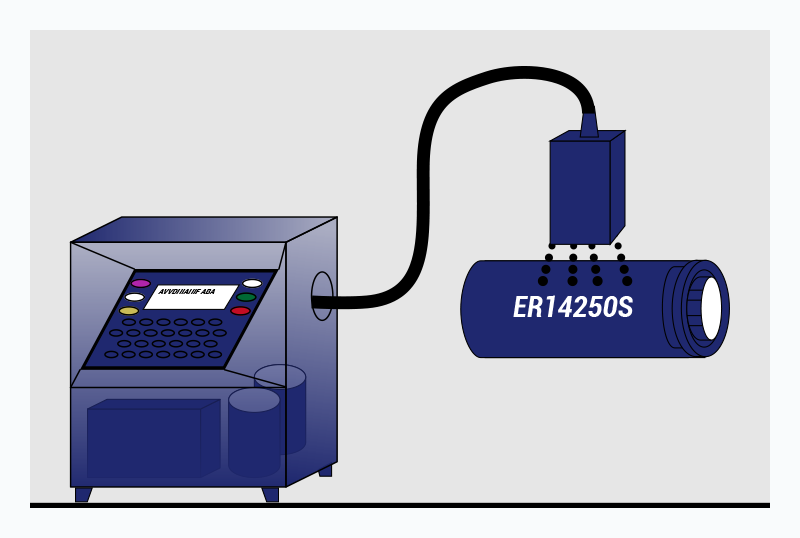

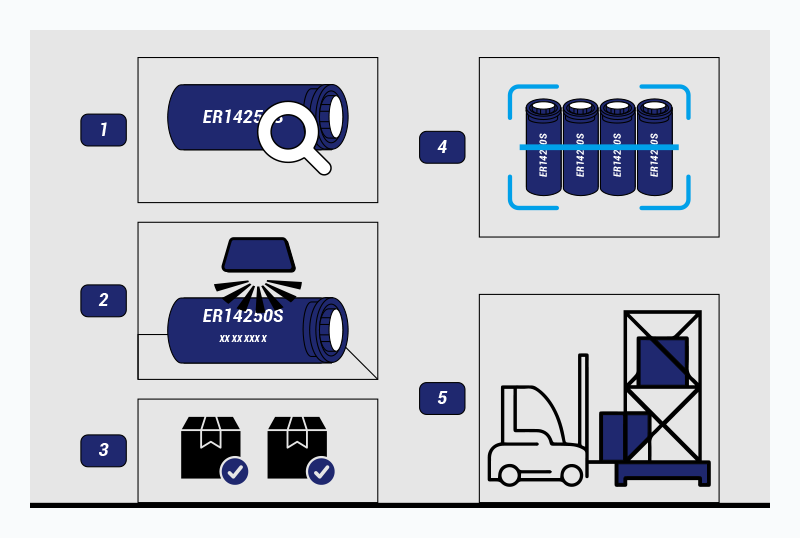

Step16: Printing code of battery shell

The printing code of battery shell is:

Material identification code

Capacity voltage printing

Manufacturing batch number

Expand knowledge

About material identification code?

Generally, it will be on the top of the battery jet terminal, such as ICR, IMR, NCR, IFR, LTO, etc.

About capacity and voltage printing?

The capacity and power will be marked on the battery.

About the manufacturing batch number?

The production batch number of each production manufacturer is different.

Requirements for printing code of lithium battery?

Lithium battery coding requirements:1. There should be no sharp objects such as scissors, steel rulers, and pens on the desktop.2……

Notes on code printing of lithium battery?

Precautions for lithium battery printing:1. Observe whether the conveyor belt of the lithium battery inkjet printer shakes or runs skewed, and if necessary, the inkjet equipment engineer maintains and corrects it.2……

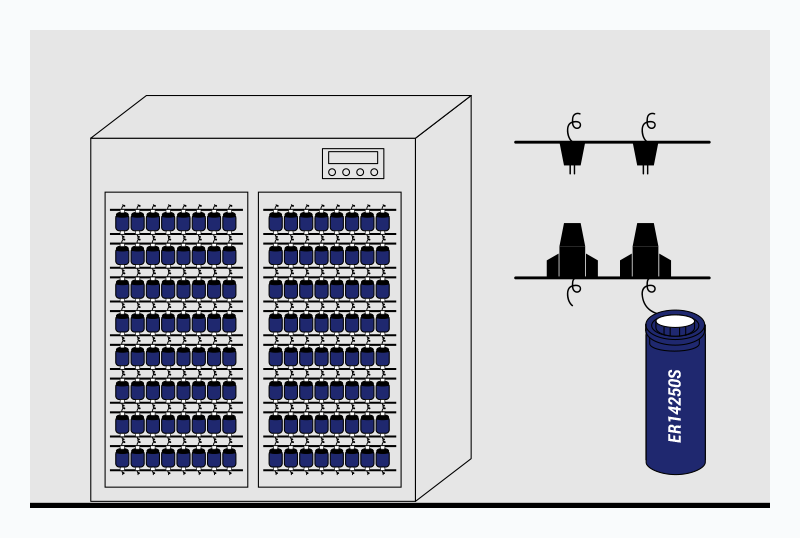

Step17: Activation and formation

The assembled battery is given a certain current.

The positive and negative active materials of the battery are excited.

After being formed, it can be used as a battery.

Expand knowledge

About the formation type of lithium battery?

Lithium battery formation is the first charging process of the battery after the lithium battery is injected.

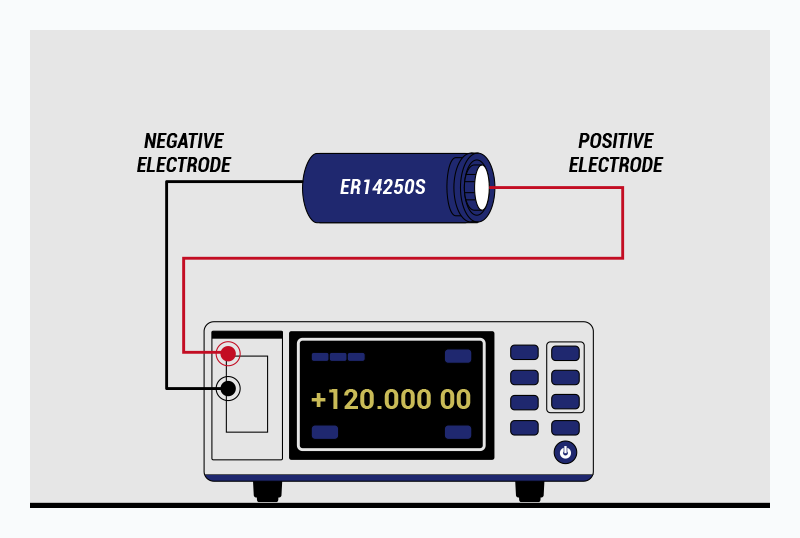

Step18: OCV measurement

OCV has two parts, OCV1 and OCV2.

OCV1 and OCV2, distinguish the open circuit voltage in different states.

Open circuit voltage measurement is one of the important inspections for detecting defective products.

Expand knowledge

About OCV?

OCV is Open circuit voltage = open circuit voltage, which refers to the potential difference between the two poles when the battery is not discharged and the circuit is open.

About the difference between OCV1 and OCV2?

OCV1 and OCV2 should be the distinction of open circuit voltage in different states.

About the measurement and detection of OCV?

Open circuit voltage (OCV) detection On the production line of lithium battery cells, the measurement of open circuit voltage is one of the important inspections for detecting defective products.

About OCV testing when to check?

OCV is the open circuit voltage. OCV detection is mainly to measure the battery characteristics by pressing the probes connected to the voltage tester and internal resistance tester on the positive and negative tabs of the pouch battery.

About OCV measurement method?

How to measure open circuit voltage:A DC voltmeter is used to measure the open circuit voltage of the cell…..

Step19: Storage at room temperature

Store lithium-ion batteries in: a cool, dry, ventilated environment.

Keep away from water, fire and high temperature.

Expand knowledge

About lithium battery storage?

Short-term storage of lithium batteries: Lithium batteries should be stored in a dry place with no corrosive gas and a temperature between -20 degrees and 35 degrees to avoid rusting of lithium battery metal parts or battery leakage.

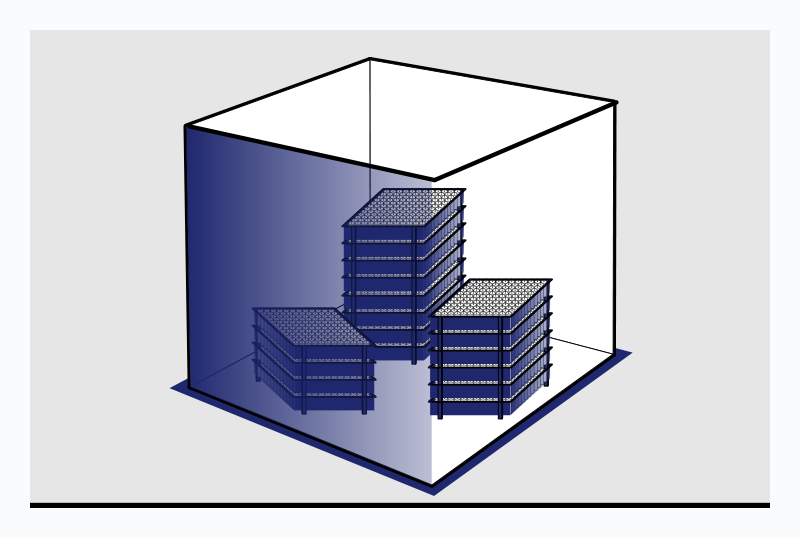

Step20: Lithium battery, sub-capacity

Capacity sorting.

Performance screening ratings.

Expand knowledge

About lithium battery capacity sorting?

When the battery capacity is divided, the data of each detection point is obtained through computer management, so as to analyze the data such as the size of the battery capacity and internal resistance, and determine the quality level of the battery.

About the purpose of lithium battery capacity sorting?

In order to improve the electrochemical performance of the battery such as cycle life, stability, self-discharge, and safety, it is necessary to strictly control the consistency of the lithium battery or accurately evaluate the battery grade.

About the capacity accuracy requirements of lithium batteries?

Therefore, there are very high requirements for the measurement accuracy of current and voltage of the formation and capacity separation equipment, which is limited to the acquisition accuracy of the sensor.

Step21: Final process

1. Full appearance inspection.

2. Spray grade code.

3. Level scan check.

4. Packaging.

5. The finished battery cells are put into storage.

Expand knowledge

About the appearance inspection?

Check the appearance and size of the lithium battery:1. The appearance of the battery must not be deformed, leaked, scratched or blown out, and the welding ends of the positive and negative wires must not be oxidized or tinned;……