What are the limitations or challenges associated with MWD technology?...

Read MoreHow does pipeline intelligent detection work?

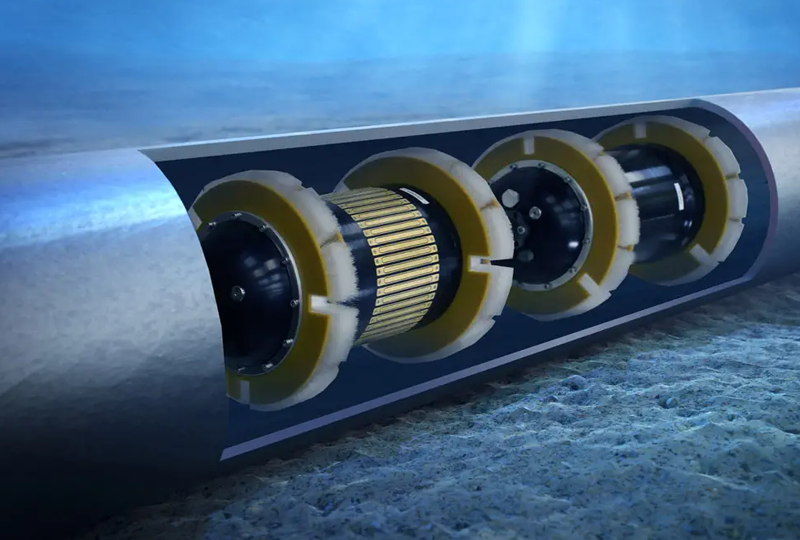

Pipeline intelligent detection, also known as pipeline cleaning or pipeline inspection and measurement (PIG), typically includes the following steps:

Preparation work: Close, drain, and clean pipelines to prepare for pigging operations. The type of pig used is selected based on the size and characteristics of the pipeline, as well as specific inspection requirements.

Launching: The pig is inserted into the pipeline through a special launching device. Pigs can be propelled by product flow in the pipeline, electric motors, compressed air, or other means.

Inspection: When the pig passes through the pipeline, it uses various sensors and instruments to collect data. The data can include measurements of pipeline thickness, temperature, pressure, and other variables, as well as images and videos of the interior of the pipeline.

Retrieve: Once the pig passes through the entire pipeline, a special receiving device is used to retrieve the pig. The data collected by the pig is then downloaded and analyzed by the computer.

Report: The inspection results are usually compiled into a detailed report, which includes information about the condition of the pipeline, any defects or anomalies detected, and repair or maintenance recommendations.

Extend Knownledges

What are the limitations or challenges associated with MWD technology?

What are the limitations or challenges associated with MWD technology?...

Read MoreAre there any limitations or considerations for using an autoclave?

Are there any limitations or considerations for using an autoclave?...

Read MoreWhat temperature and pressure are typically used in an autoclave?

What temperature and pressure are typically used in an autoclave?...

Read More