What are the limitations or challenges associated with MWD technology?...

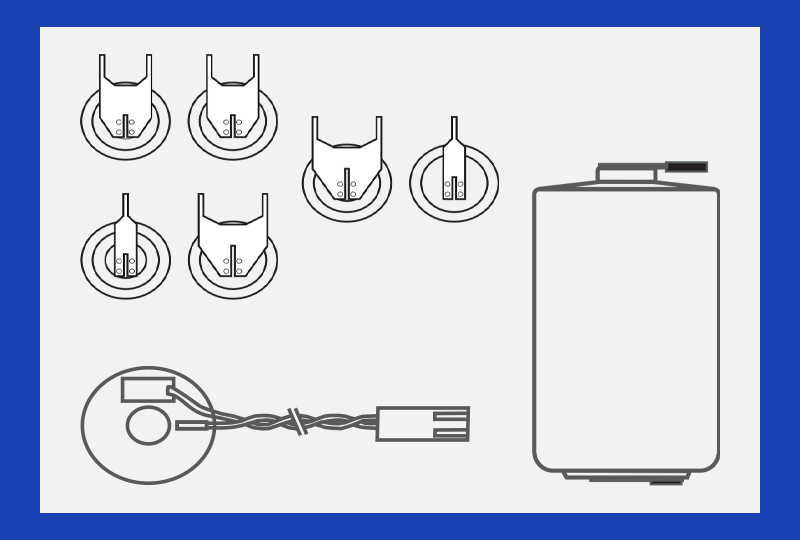

Read MoreWhat are the types of high temperature battery pins?

High-temperature battery pins are typically used in high-temperature applications, such as in oil and gas drilling, aerospace, and military applications. These pins must be able to withstand extreme temperatures, vibration, and other harsh environmental conditions while maintaining reliable electrical contact.

There are several types of high-temperature battery pins, including:

Solder pin: Solder pins are commonly used in high-temperature applications because they can withstand temperatures up to 350°C. These pins are made of a high-temperature alloy, such as Kovar or Inconel, and are attached to the battery or device using solder.

Compression pin: Compression pins are made of a conductive material, such as copper or brass, and are designed to provide reliable electrical contact in high-temperature environments. These pins use a spring or other mechanism to maintain contact with the battery or device.

Weld pin: Weld pins are similar to solder pins, but instead of using solder, they are attached to the battery or device using a welding process. Weld pins can withstand higher temperatures than solder pins, typically up to 600°C.

Crimp pin: Crimp pins are made of a conductive material, such as copper or brass, and are designed to be crimped onto the battery or device using a specialized crimping tool. These pins can withstand high temperatures and are commonly used in aerospace and military applications.

Extend Knownledges

What are the limitations or challenges associated with MWD technology?

What are the limitations or challenges associated with MWD technology?...

Read MoreAre there any limitations or considerations for using an autoclave?

Are there any limitations or considerations for using an autoclave?...

Read MoreWhat temperature and pressure are typically used in an autoclave?

What temperature and pressure are typically used in an autoclave?...

Read More