Why are high-temperature lithium-ion batteries more suitable for Autoclaves data...

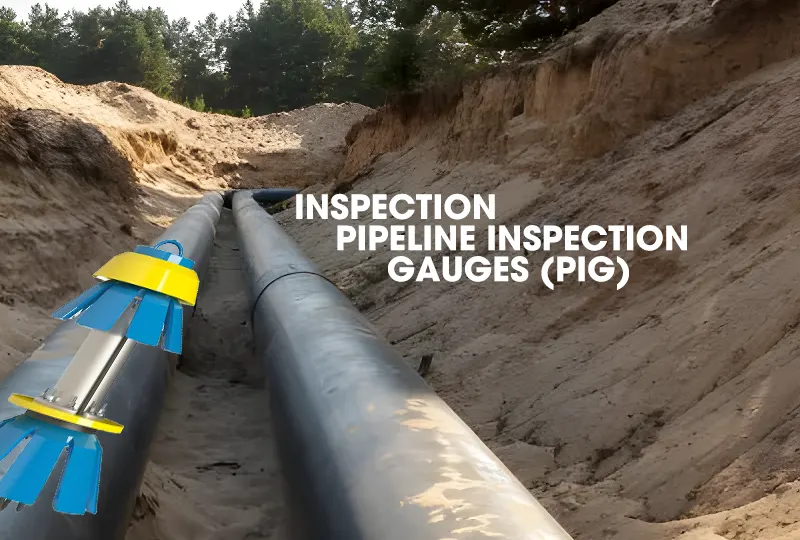

Read MoreHow does Inspection Pipeline Inspection Gauges (PIG) work?

Pipeline Inspection Gauges (PIG) are equipment used to inspect oil and gas pipelines. They are a cylindrical device, moderately sized, that move inside the pipe. PIGs usually consist of a series of devices with sensors that detect various parameters of the pipeline, such as pressure, flow, temperature and corrosion.

PIG works by putting it inside a pipe and propelling it through the pipe. There are usually two propulsion methods for PIG: hydraulic propulsion and compressed gas propulsion.

In hydraulic propulsion, high-pressure liquid is pumped into the pipeline, pushing the PIG into the pipeline. In the case of compressed gas propulsion, compressed air or nitrogen is introduced into the pipeline to propel the PIG forward within the pipeline.

Once PIG enters the pipeline, it starts executing tasks. It collects various parameters within the pipeline and sends this data back to the host computer for analysis. In addition, PIG can detect and report on damage, corrosion and other problems in the pipeline.

Extend Knownledges

What issues have lithium-ion batteries helped Autoclaves data loggers solve?

What issues have lithium-ion batteries helped Autoclaves data loggers solve?...

Read MoreAutoclaves data loggers how much voltage Li-ion battery?

Autoclaves data loggers how much voltage Li-ion battery? https://youtu.be/GSAtWWPmBRc The...

Read MoreWhat is the effect of lithium-ion batteries on Autoclaves data loggers?

What is the effect of lithium-ion batteries on Autoclaves data...

Read More