Why are high-temperature lithium-ion batteries more suitable for Autoclaves data...

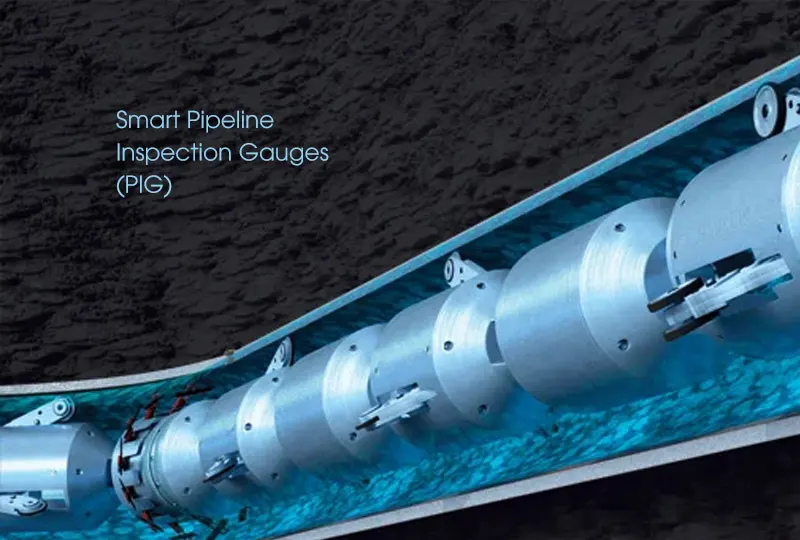

Read MoreHow does Smart Pipeline Inspection Gauges (PIG) detect pipeline problems?

The following is the general process of smart PIG detecting pipeline problems:

1. Front-end sensors: There are usually multiple sensors at the front-end of the PIG that can collect data inside the pipeline. For example, pressure sensors detect pressure changes in pipes, temperature sensors detect temperature changes in pipes, magnetic sensors detect magnetic materials on pipe walls, etc.

2. Data collection: When the PIG is running, the data collected by the front end is transmitted back to the computer or data storage center.

3. Data analysis: The computer on the PIG conducts data analysis and compares the detected data with the specifications and historical data of the pipeline to determine whether there is a problem.

4. Find problems: If PIG detects problems such as foreign matter, corrosion, wear, cracks, leakage, etc. in the pipeline, it will immediately record and issue an alarm to notify the pipeline operator for maintenance.

Extend Knownledges

What issues have lithium-ion batteries helped Autoclaves data loggers solve?

What issues have lithium-ion batteries helped Autoclaves data loggers solve?...

Read MoreAutoclaves data loggers how much voltage Li-ion battery?

Autoclaves data loggers how much voltage Li-ion battery? https://youtu.be/GSAtWWPmBRc The...

Read MoreWhat is the effect of lithium-ion batteries on Autoclaves data loggers?

What is the effect of lithium-ion batteries on Autoclaves data...

Read More