What are the limitations or challenges associated with MWD technology?...

Read MoreIn the production of high-temperature batteries, what is the detection alignment of the batteries?

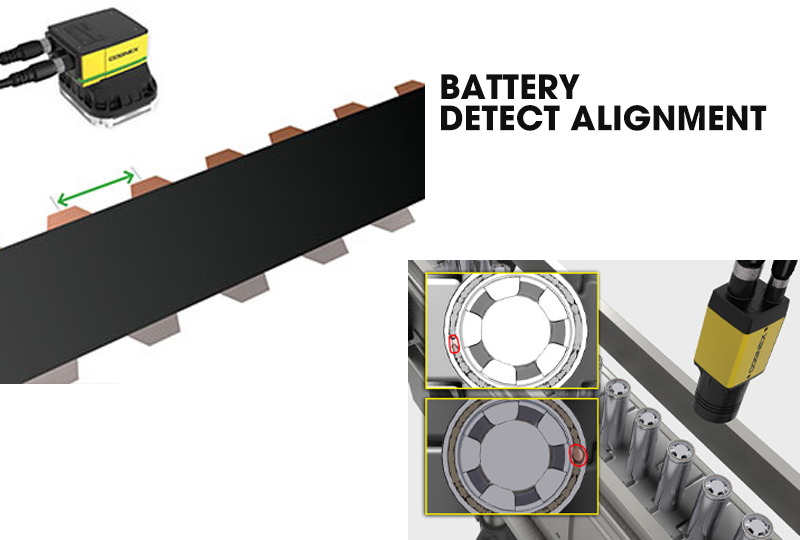

In the production of high-temperature batteries, “detection alignment” typically refers to the process of checking and aligning the battery components to ensure that they are properly positioned and connected.

During battery assembly, it is essential to ensure that the components, including the electrodes, separator, and current collectors, are correctly aligned and connected to ensure that the battery functions as intended. Detection alignment is achieved through various methods, including visual inspection, measurement, and testing.

Visual inspection involves physically examining the battery components to ensure that they are properly positioned and connected. Measurements may be taken to check the thickness and uniformity of the electrode coating or to verify the alignment of the electrode and current collector. Testing may also be performed to check the electrochemical performance of the battery.

In addition to ensuring proper detection alignment during battery assembly, it is also important to periodically monitor and check the alignment of the battery components during operation. This can be achieved through techniques such as impedance spectroscopy, which can detect changes in the battery’s electrochemical behavior and identify potential issues with component alignment or connection.

Extend Knownledges

What are the limitations or challenges associated with MWD technology?

What are the limitations or challenges associated with MWD technology?...

Read MoreAre there any limitations or considerations for using an autoclave?

Are there any limitations or considerations for using an autoclave?...

Read MoreWhat temperature and pressure are typically used in an autoclave?

What temperature and pressure are typically used in an autoclave?...

Read More