What are the limitations or challenges associated with MWD technology?...

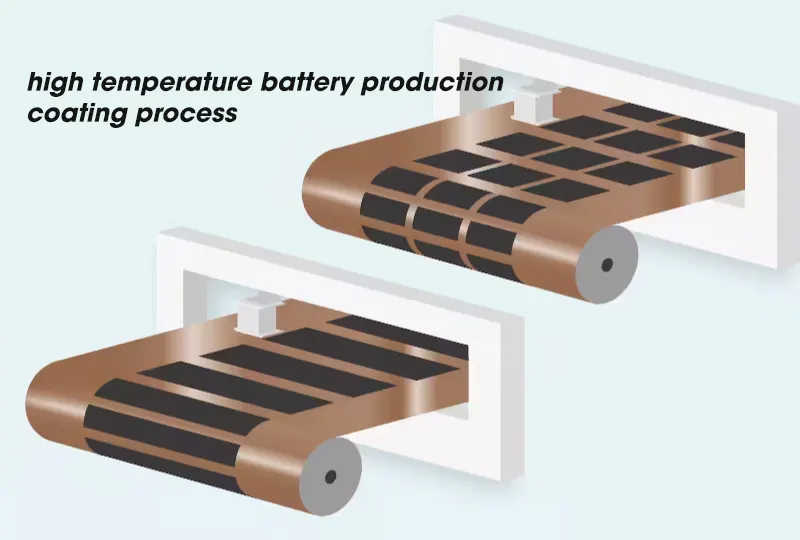

Read MoreWhat is the coating process in high temperature battery production?

The coating process in high temperature battery production involves the application of a thin layer of active material onto a current collector substrate. This process is critical in the manufacture of high-temperature batteries because it directly affects the battery’s performance, reliability, and durability.

There are different coating methods used in high temperature battery production, including doctor-blade coating, slot-die coating, and spray coating. Doctor-blade coating is the most commonly used method for the coating of high-temperature battery electrodes. It involves the use of a blade to spread a slurry of active material over the surface of the current collector substrate. The thickness of the coating is controlled by adjusting the gap between the blade and the substrate.

The slurry used in the coating process is a mixture of active material, conductive additives, and a binder. The active material is the substance that undergoes electrochemical reactions during battery operation. The conductive additives are included to improve the conductivity of the electrode, while the binder is used to hold the active material and conductive additives together.

After the coating process, the electrodes are dried to remove any solvent present in the slurry. The drying temperature and duration are critical factors that affect the morphology and electrochemical performance of the electrode.

Extend Knownledges

What are the limitations or challenges associated with MWD technology?

What are the limitations or challenges associated with MWD technology?...

Read MoreAre there any limitations or considerations for using an autoclave?

Are there any limitations or considerations for using an autoclave?...

Read MoreWhat temperature and pressure are typically used in an autoclave?

What temperature and pressure are typically used in an autoclave?...

Read More