Information

What are the different types of pipeline inspection instruments?

There are several types of pipeline inspection instruments used for different purposes. Here are some of the most common:

What is pipeline intelligent pig detection?

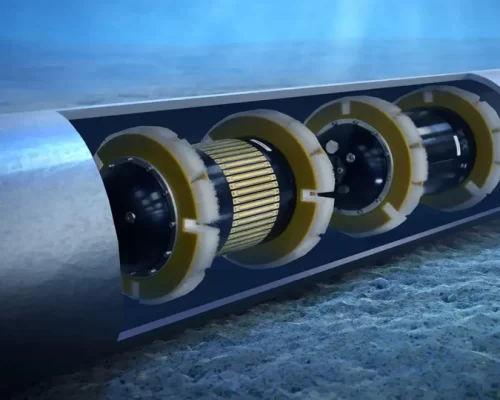

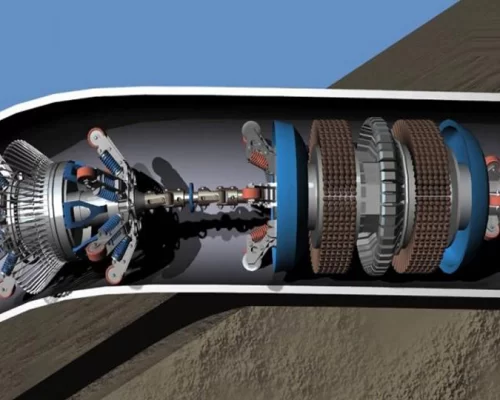

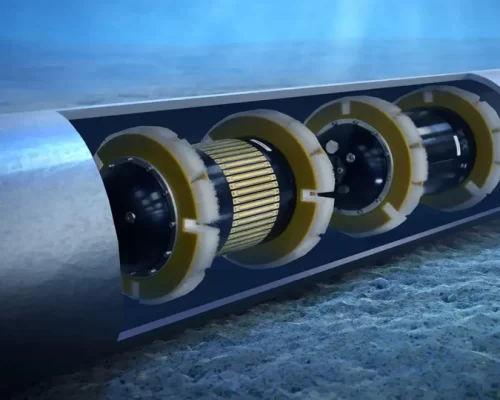

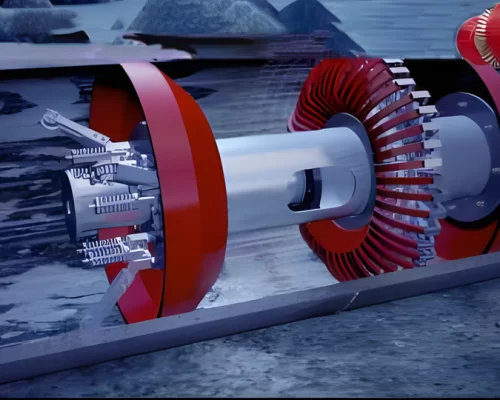

Pipeline intelligent pig detection, also known as pipeline cleaning or pipeline inspection measurement (pig), is a method of inspecting pipelines internally using a tool called a pig.

2023/04/25

How does pipeline intelligent detection work?

Pipeline intelligent detection, also known as pipeline cleaning or pipeline inspection and measurement (PIG), typically includes the following steps:

What are the advantages of using high-temperature batteries for pipeline detectors?

High temperature batteries provide several advantages for pipeline detectors, including:

Why do pipeline detectors choose to use high-temperature batteries?

There are several reasons why high-temperature batteries are chosen for pipeline detectors, including:

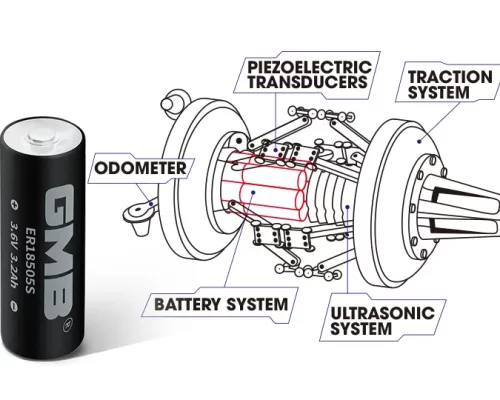

What is the working principle of a pig detector?

A pig detector is a device used to detect and track the movement of pipeline cleaning equipment (referred to as a “pig”) in pipelines. The working principle of a pig detector is based on the detection of the magnetic field generated by the pig moving in the pipeline.

What is a pig detector?

A pig detector is a device used in the oil and gas industry to detect and track the movement of pipeline cleaning equipment “pigs” in pipelines.

How does a pig detector work?

A pig detector, also known as a pig detector, is a device used to detect the presence of a pig or pipeline inspection instrument in pipelines.

What is the purpose of pigging in Pipeline inspection?

Pigging in pipeline inspection is the process of using pipeline inspection instruments or “pigs” to clean, inspect, or maintain pipelines. The following are some of the main purposes of pipeline cleaning during pipeline inspection:

2023/04/26-29

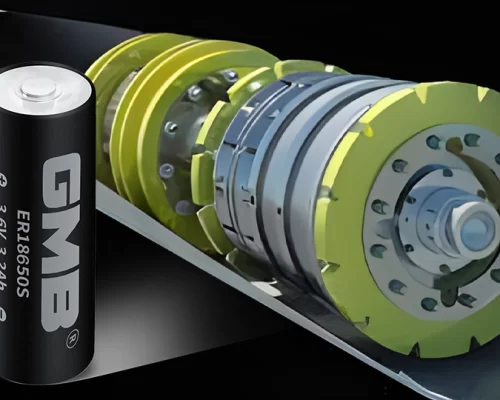

How is the high temperature battery ER18650S used in Pipeline inspection gauges (PIG) equipment?

One of the advantages of the ER18650S battery is its ability to operate at high temperatures, which is important for PIGs that are used in pipelines where the temperature can be elevated.

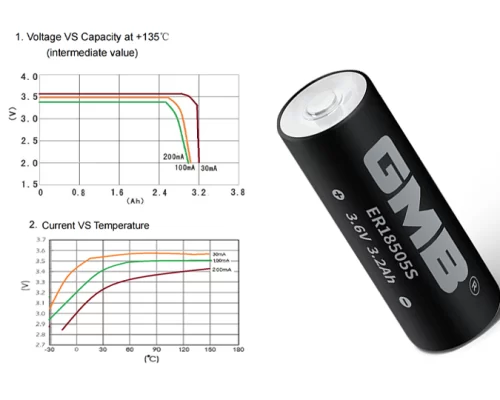

What are the basic parameters of the Pipeline inspection gauges (PIG) high temperature battery unit ER18505S?

Wide operating temperature range (-30°C ~+150°C), low self-discharge rate (annual self-discharge rate is less than 3% at +25°C).

How safe is the high-temperature battery ER18650S in Pipeline inspection gauges (PIG) equipment?

When used in PIG equipment, the ER18650S battery may be subjected to high temperatures, pressure, and vibration, which can affect its performance and safety.

About the high temperature battery characteristics of ER18505S used in Pipeline inspection gauges (PIG) equipment?

R18505S primary high-temperature battery has the characteristics of long shelf life, high performance, high reliability, low self-discharge rate,

2023/05/05-06

Why did Pipeline inspection gauges (PIG) choose high temperature ER18505S batteries to power the equipment?

The high-temperature ER18505S battery is an excellent choice for powering PIG equipment due to its high energy density, long life, wide temperature range, low self-discharge rate, availability, and cost-effectiveness.

What should be paid attention to when using high-temperature ER18650S batteries in Pipeline inspection gauges (PIG) equipment?

1. Work within the specified temperature range of the battery. Exceeding the recommended temperature range may cause permanent damage to the battery and shorten its service life.

2023/05/08-13

How to tell if the high temperature battery in the Pipeline inspection gauges (PIG) tool is low?

Most PIG tools have a built-in battery indicator that displays the current battery level.

How to correctly replace high temperature battery from Pipeline inspection gauges (PIG)?

Replacing the high-temperature battery in a Pipeline Inspection Gauge (PIG) typically involves the following steps:

Identify the battery type: Determine the specific type of high-temperature battery used in your PIG tool.

How to properly dispose of high temperature batteries used in Pipeline inspection gauges (PIG)?

Here are some steps to dispose of them properly:

1. Contact the manufacturer or supplier, who may provide specific instructions or direct you to the appropriate disposal channel.

What should be paid attention to when handling high-temperature batteries after use in Pipeline inspection gauges (PIG)?

The following precautions must be observed to ensure safety when after-processing high-temperature batteries used in pipeline inspection gauges (PIGs):1. Wear appropriate personal protective equipment, including gloves, safety glasses, and possibly a lab coat or coverall.

What is the role of Cleaning Pipeline Inspection Gauges (PIG)?

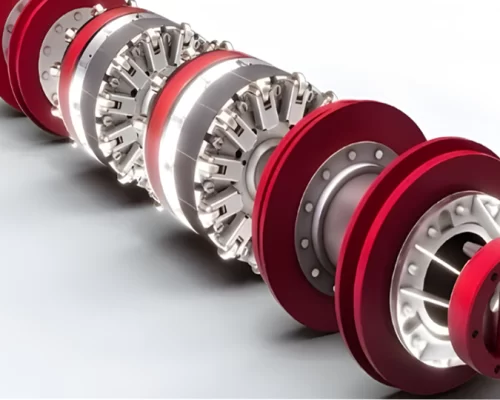

The following are several main functions of PIG:Clean pipes: PIG can remove sediment, dirt and other impurities from the inside of pipes. By moving inside the pipe, the PIG is able to scrape or push the dirt, dislodging it from the pipe walls.

What are the main parameters to look for when purchasing Pipeline Inspection Gauge (PIG) high temperature batteries?

Here are some key parameters and features to focus on:Pay attention to the operating temperature range of the battery. Make sure that the selected battery can work well in high temperature environment, and has the adaptability and reliability.

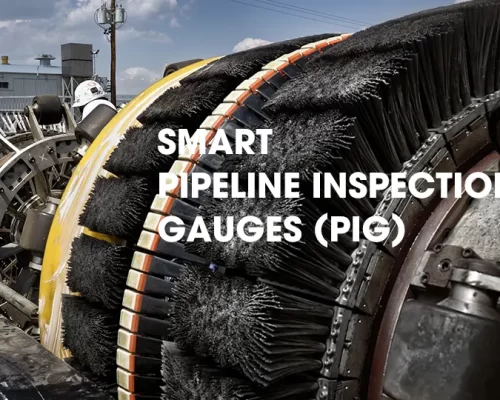

How does Smart Pipeline Inspection Gauges (PIG) work?

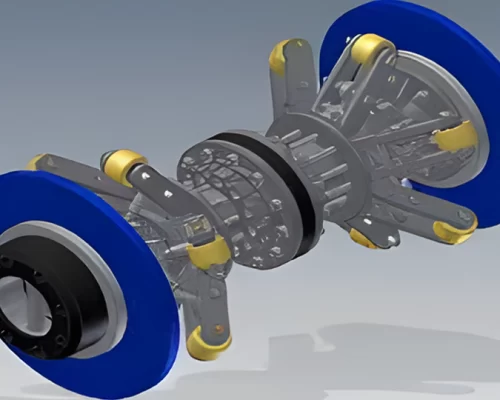

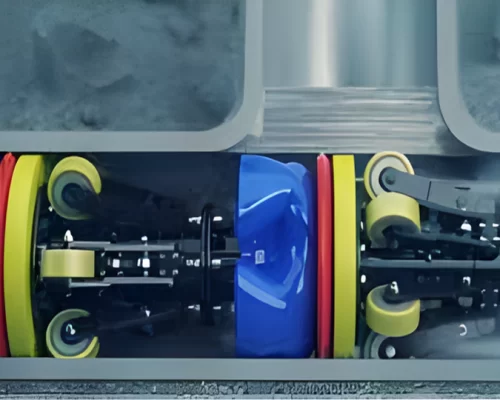

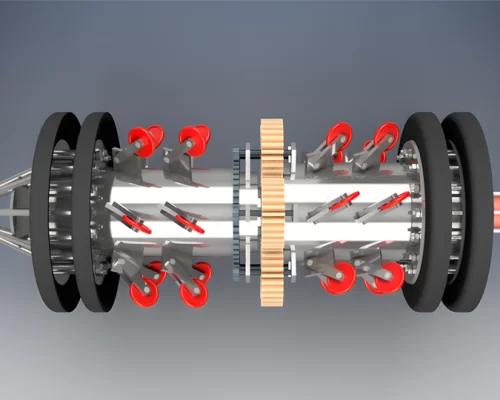

The working method of Smart Pipeline Inspection Gauges (Smart PIG for short) can be briefly summarized as the following steps:Smart PIG is first deployed into the pipeline to be inspected and activated at the pipeline entrance. It can enter the pipeline in various ways, such as by pressure, fluid push or mechanical assistance.

What types of pipelines are Pipeline inspection gauges (PIG) used in?

Pipeline Inspection Gauges (PIG) can be applied to many types of pipelines, including crude oil and natural gas pipelines, water and sewage pipelines,

What are the requirements for Pipeline inspection gauges (PIG) in pipeline applications?

Requirements for PIG include accuracy and reliability, adaptability and flexibility, security, data collection and transmission capabilities,

2023/05/19-27

What form of electricity does the Pipeline inspection gauges (PIG) run on?

Pipeline Inspection Gauges (PIG) are usually powered by an internal battery in use.

What is the internal battery type of Pipeline inspection gauges (PIG)?

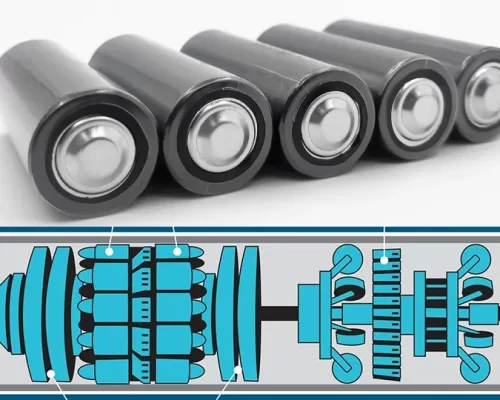

The battery used inside the Pipeline Inspection Gauges (PIG) is a battery pack (Battery Pack).

What is the internal battery composition of Pipeline inspection gauges (PIG)?

Series Connection,This form is often used in PIG equipment that needs to provide higher voltage.Parallel Connection,This form is often used in PIG equipment that needs to provide a large current.

2023/05/29-31

How to determine the size of the Pipeline inspection gauges (PIG) battery pack?

The capacity of the battery pack required by PIG needs to comprehensively consider factors such as the service time, power consumption, environmental conditions and size of the device.

What is the integrity of Pipeline inspection gauges?

The integrity of pipeline inspection gauges refers to their reliability, accuracy, and ability to effectively perform their intended tasks.

What are the safety standards for Pipeline inspection gauges?

Pipeline inspection gauges, also known as “PIGs,” are subject to various safety standards to ensure their safe operation and minimize risks during pipeline inspection and maintenance activities.

2023/06/1-3

What are the hydrodynamic properties of Pipeline inspection gauges?

Pipeline inspection gauges, commonly known as pigs, have various hydrodynamic properties that enable them to traverse through pipelines and perform their intended functions.

What is the role of Pipeline inspection gauges Stability and Maneuverability?

PIGs need to maintain stability and maneuverability while traveling through the pipeline.

2023/06/5-10